Author: Natalia Reen, Åbo Akademi University

Introduction

This spring, I spent three months in La Spezia, Italy, as part of a research exchange from Åbo Akademi University to the University of Genoa. During my exchange I was involved in the LeaderSHIP project—an initiative focused on aligning future education and training with the maritime sector’s green transition. I contributed to various activities including co-authoring academic paper, developing new maritime education curricula, and designing and piloting lectures.

As part of this experience, and thanks to the invitation from Professor Cesare Mario Rizzo, I had the rare opportunity to visit the cutting-edge Testing Facility at the University of Genoa (UniGe). Launched in 2018 and developed under a European H2020-funded project (ROBINS, ROBotics technology for INspection of Ships), the facility is designed to enable standardized and repeatable tests and trials.

Its core objective is to provide a cost-efficient, purpose-built controlled environment for developing, testing, and piloting Robotic and Autonomous Systems (RAS) in conditions that closely mimic real-world scenarios.

Seeing the facility firsthand gave me invaluable insight into how different technologies are being developed and applied for ship inspection. I was able to observe the real testing environment, explore various tools, and understand how the modular steel structures replicate the interior of actual ship compartments. Indeed, scrapped parts of real ships were reassembled within the Marine Structures Testing Lab and the Drives and Experimental Automation for Marine Systems Lab at UniGe, forming the foundation of the current Testing Facility.

When Robots Meet Shipbuilders: A New Era in Vessel Inspections

Ship inspections are critical to maritime safety, but the process largely remains manual, expensive, and hazardous. Surveyors spend dozens of hours each year navigating tight spaces, climbing internal structures, and relying on their experience to spot corrosion, cracks, or structural defects. Inspection costs can be significant—especially for large or complex vessels such as tankers or cruise ships—often reaching tens of thousands of euros per year when accounting for regulatory, classification, and operational requirements.

As the maritime world embraces digital transformation, the push to find smarter, safer, and more efficient ways to inspect ships is fuelling innovation in exiting and unexpected directions. Robotics, AI, and naval architecture are coming together to completely rethink how we look at ship structures.

Now, the Testing Facility is exploring how Robotic and Autonomous Systems (RAS) and more in general any digital technology can be integrated into inspection routines—not to replace human expertise, but to enhance it. These systems are being developed as collaborative tools that help reduce risk, improve efficiency, and support more consistent and high-quality inspections across the maritime sector.

More than just a laboratory, this environment is designed to mimic the real-world conditions of shipboard inspections. Its main module replicates the layout and structure of a bulk carrier’s cargo hold and ballast tanks, complete with authentic steel components salvaged from decommissioned vessels—bearing real rust, pitting, cracks, distortions, and mechanical damage.

What makes this facility stand out is its combination of modular design and realistic conditions. Variables such as cleanliness, lighting, air humidity, and various sources of disturbances can be adjusted to create a wide range of repeatable testing scenarios. This enables researchers to safely simulate inspections in environments that would be difficult or dangerous or simply impossible to access on real ships to develop and validate the technologies as well as train their users.

Three steps of assessments

The Testing Facility is structured into three key parts, each simulating a certain stage of inspection:

- Specific and Separate Tests – Robots such as drones and crawlers undergo isolated, time-sensitive tests to evaluate core functions like flight stability and surface adhesion. These assessments ensure that robots can be reliable for data collection on defect characteristics like size, location, and material thickness.

- Human-Equivalent Inspection Tasks – Robots replicate typical tasks performed by human surveyors, measuring both the accuracy and efficiency of contact or non-contact operations. These activities are carried out in controlled lab conditions that mimic real-world ship inspections and compared with human performances.

- Realistic Ship Environment Simulation – A standout feature of the facility is its life-sized reproduction of ship sections, aged and degraded to reflect true maritime conditions. Here, robots are tasked with detecting a variety of defects—such as corrosion, cracks, pitting, and welding flaws—while operating under challenging conditions like low lighting, turbulence, high humidity, and artificial fog. These scenarios closely replicate the realities of onboard inspection environments.

Testing Protocols with Real-world Consistency

Beyond the physical setup, the Testing Facility team developed rigorous testing protocols that evaluate robotic platforms on a wide range of performance metrics: mobility, localization, visual clearness, and defect detection and sizing. These standardized procedures help evaluate how RAS perform in tasks ranging from localization and navigation to defect detection and data collection and compare with humans’ performances.

The goal is to reach a point where RAS can provide data equivalent or even better than a human surveyor would gather through direct inspection.

For example, in a key trial, a human surveyor and a RAS pilot team were asked to identify structural defects across a defined inspection path. Both performed comparably in time and accuracy, suggesting that RAS-assisted inspections can already meet the standards expected of traditional methods.

Examples of Robots in Action

During my visit I was introduced to various testing platforms through discussions with Professor Rizzo, who described several use cases and practical examples of their deployment. The platforms included:

- Aerial Drones – Compact and robust, these drones can navigate narrow steel compartments and capture wide-angle imagery even in challenging conditions. They also carry onboard sensors to collect diverse inspection data.

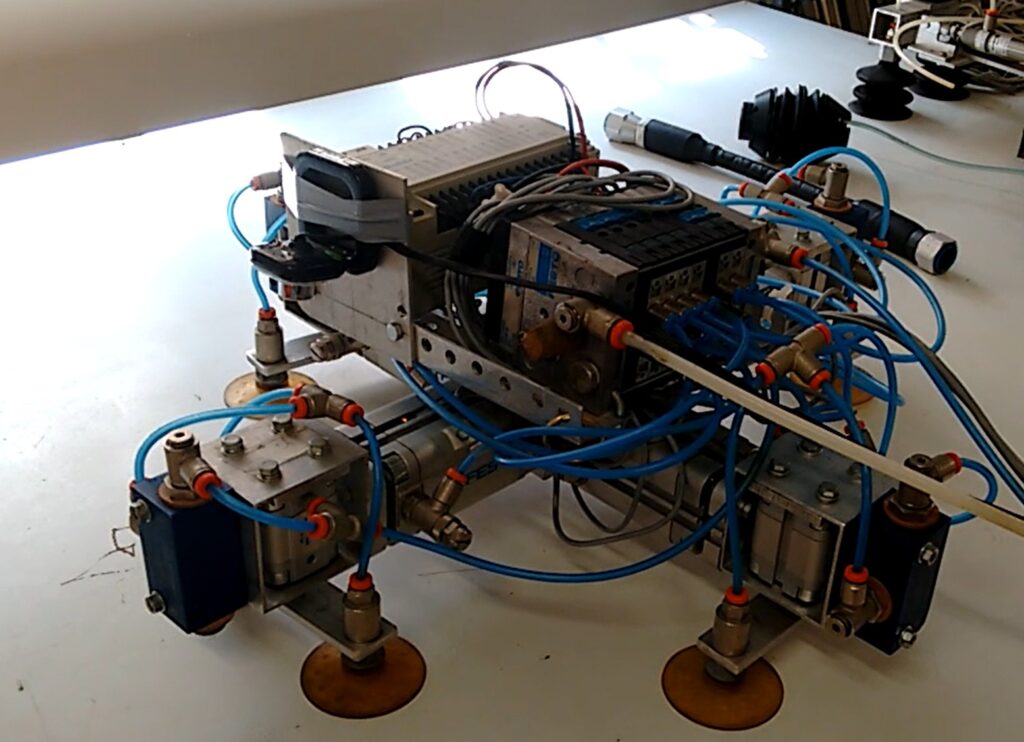

- Magnetic Crawlers – Designed to adhere to vertical and overhead surfaces, these robots conduct close-up inspections and perform thickness measurements with high accuracy.

- Climbing (legged) Units – Inspired by biological movement, these zoomorphic climbers use suction or magnetic adhesion to scale structural components, manoeuvre through tight joints, and inspect weld seams.

Each platform is subjected to rigorous trials to measure not just mechanical performance, but also data quality—such as whether a robot’s thickness measurement matches that of a human, within acceptable tolerances.

Different sections of the environment can be configured to mimic specific challenges found on board—such as narrow steel compartments, varying lighting, or high humidity. For example, testing modules include:

- Obstacle Navigation – Magnetic crawlers must manoeuvre over beams and around structural obstacles.

- Visual Capability – Drones are tested in low-light, high-dust environments for camera stability and image quality.

- Sensor Accuracy – Ultrasound and thickness measurement tools are validated against industry-standard readings.

Why Test Facility Matters

The implications of the facility and its robotic platforms are far-reaching:

- Safety – RAS platforms reduce the need for surveyors to access confined or hazardous areas, significantly lowering risk.

- Efficiency – Robots can cover larger surface areas in less time, often eliminating the need for scaffolding or dry-docking.

- Standardization – The facility is helping to establish the foundation for future international standards in robotic ship inspections.

However, it’s important to note that performance assessments are currently limited to controlled environments. In real ship conditions, the location, extent, and type of structural degradation are unknown—making field deployment significantly more complex.

Even more exciting is the vision for the future: robotic inspections, once validated as reliable and accurate, feeding directly into digital twins of vessels, enabling continuous monitoring, predictive maintenance, and even remote certifications. The facility is now equipped with a high-speed internet connection and a multi-camera video-streaming system, enabling remote trials. This setup is particularly valuable for studying the human factor in the adoption of digital and robotic technologies—supporting the evaluation and adaptation of current practices and workflows.

While RAS platforms are not yet fully autonomous, their development is progressing rapidly. The facility demonstrates that, in the coming years, structured protocols and collaborative workflows could enable human surveyors and robotic assistants to operate in close synergy. In the future, surveyors may be able to remotely supervise and manage multiple robotic units—interpreting inspection data from across an entire fleet without ever setting foot onboard. However, reaching this level of integration will require sustained effort in system development, validation, and regulatory adaptation.

As the industry looks ahead, standardizing RAS testing protocols and establishing international certifications are critical next steps. By turning laboratories into scalable, repeatable inspection grounds, Testing Facility is not only pioneering robotics for today’s ships but laying the foundation for digital twins, real-time monitoring, and predictive maintenance in the ships of tomorrow.

Living Labs and Nordic Collaboration

This initiative echoes Green Transition Lab in Finland, where Åbo Akademi University and Meyer Turku have explored various themes in automation, digitalization, and data-driven services development for ships and shipbuilding. These industrial-academic collaboration resemble what many are now calling “living labs”—spaces where technology, regulation, and human practice intersect in a dynamic and interactive environment.

The Genoa facility aligns well with this trend. By offering a modular and reproducible test environment, it supports collaborative learning, regulatory readiness, and international alignment—key ingredients for accelerating safe, scalable adoption of inspection robotics in the maritime sector.

Concluding remarks

The Testing Facility of University of Genoa and Green Transition Lab in Finland prove that innovation isn’t just about futuristic hardware—it’s about new ways of working, shift toward sustainability, redefining workflows, improving safety, and empowering human experts with better tools.

Thanks again to Professor Rizzo and the University of Genoa for providing a firsthand look into how research and engineering are reshaping maritime safety from the inside out.

Natalia Reen, Senior Researcher, Åbo Akademi University.